Preserve and extend the life of your critical infrastructure with industry-leading cathodic protection solutions.

Cathodic protection is a proven technology for mitigating corrosion on submerged, buried, and atmospherically exposed reinforced concrete structures. We're your source for cathodic protection design, inspection, and corrosion management solutions.

If you work with reinforced concrete structures likes bridges, parking garages, industrial buildings, power/dams, or marine structures you know the importance of durability over a structure’s required service life. We aim for durability at low maintenance costs.

Cathodic protection systems help preserve critical infrastructure and extend service life, but it’s critical that these systems are correctly designed, implemented, and maintained.

VCS Engineering offers comprehensive cathodic protection services, including design, contractor training, QA/QC, and system monitoring technologies and construction plans. Our NACE-certified experts specialize in reinforced concrete corrosion, with service that exceeds our clients' expectations.

Methods

Our experts will help you determine which methods are most effective and economical for your needs.

Cathodic Protection Design

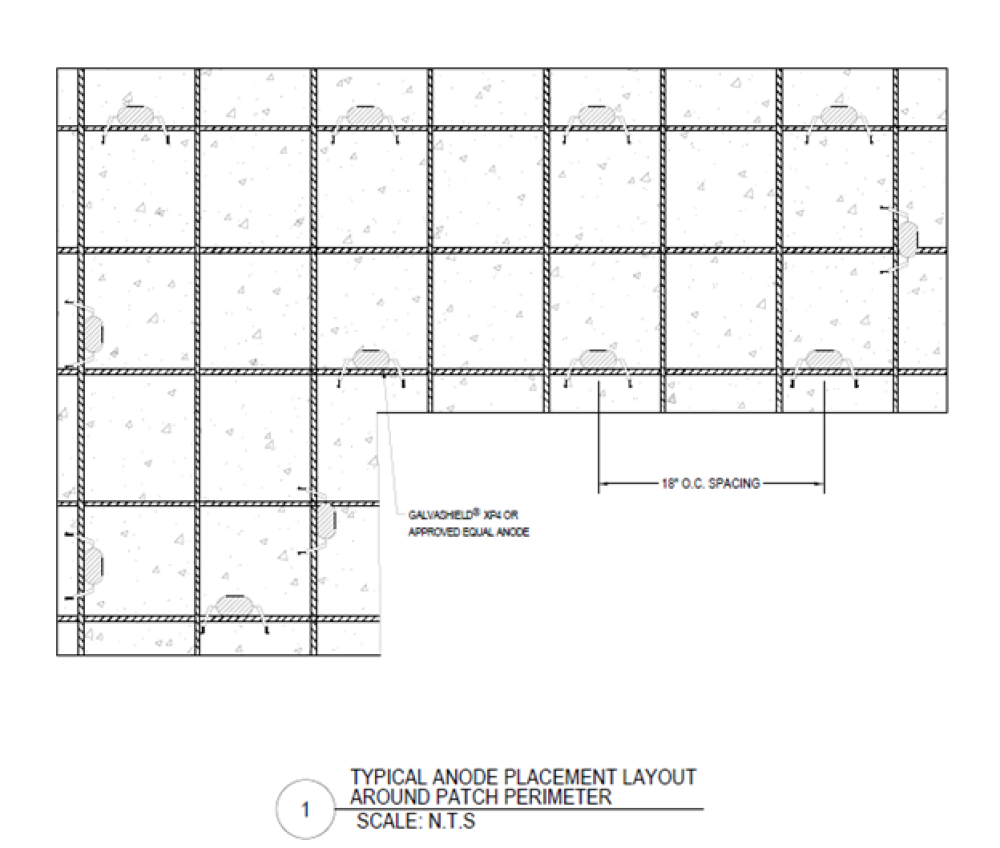

Corrosion mitigation strategies vary in cost, expected service life extension, and application. We have experience across different industries and structures in various environmental conditions. We’ll outline a range of strategies to help you make informed decisions. We provide high-value designs with drawings and specifications to include in project bid packages.

Contractor Training and Quality Control

We work with contractors and owners to ensure galvanic and ICCP systems are installed to specifications and functioning properly.

CP installations require a NACE-certified technician to be on-site — full-time or regular visits — to verify the installation meets the system's specifications. Our technicians can fill that role, working directly with contractors so they know how to install the system properly.

We also represent owners on installations, ensuring contractors follow bid documents to meet design expectations. We have the required calibrated meters and reference electrodes used in QA/QC applications.

Existing System Inspection and Troubleshooting

Repairing impressed current cathodic protection (ICCP) systems starts with determining the current system status and identifying deficiencies.

We evaluate:

- system wiring

- anode condition

- system current delivery

- reference electrodes

- monitoring equipment

- components and procedures to troubleshoot CP systems

We diagnose issues, adjust system outputs to meet NACE CP criteria, and provide support in repairing any damaged components.

System Maintenance and Management

CP systems require monitoring, management, and maintenance to protect a structure sufficiently.

We work with owners of CP systems to ensure equipment and systems are continuously operating to provide proper corrosion mitigation. System management ranges from remote monitoring using data loggers and communication devices to regular site visits.

We provide regular reports highlighting the system's performance and identifying maintenance needs. If issues arise, we correct them and ensure the system works quickly.

Project Experience

We provide extensive experience across a range of structures and environmental conditions.

Where it Applies

Service offerings are relevant across these sectors.