Promenade Over FDR Dr

Services Applied by VCS Engineering

Project Description

The Promenade over FDR drive between E 81st and E 90th Street is a large pedestrian and bicycle corridor over a major vehicle artery. The Promenade consists of 53 spans that include steel and reinforced concrete structural elements. The structure was constructed in 1942 and is currently showing signs of concrete and steel deterioration, such as cracking, spalling and corrosion. The New York City Department of Transportation (NYCDOT) contracted Hardesty & Hanover (H&H) to perform an assessment of the FDR Promenade structure to determine its current condition and develop a rehabilitation strategy.

Project Scope

The New York City Department of Transportation (NYCDOT) contracted Hardesty & Hanover (H&H) to perform an assessment of the FDR Promenade structure to determine its current condition and develop a rehabilitation strategy.

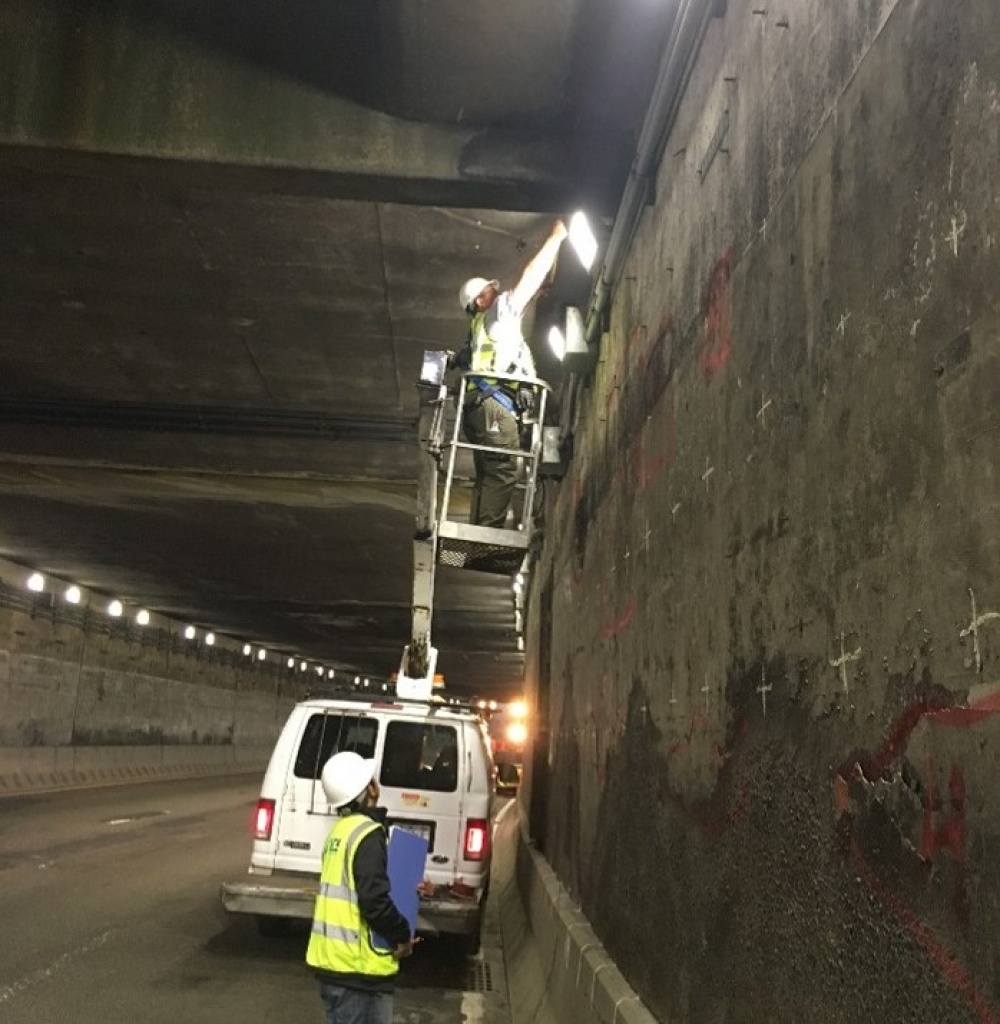

As part of the H&H Team, VCS performed a corrosion and material evaluation of the Promenade with the objective of identifying the root cause of the deterioration, the extent of damage beyond the visual assessment, and providing the information necessary to design lasting and effective repairs.

VCS conducted a concrete material and corrosion assessment of the various elements of the FDR Drive structure using several non-destructive (NDT) and material sampling techniques. NDT was used to identify the extent of concrete deterioration. The NDT methods implemented were corrosion potentials, ground penetrating radar, and impact echo. Material sampling was done in the form of concrete cores removed from various structure elements. The cores were used for petrographic analysis, chloride ion diffusion analysis, concrete resistivity measurement, carbonation depth, and compressive strength testing.

Project Solution

Upon completing the extensive fieldwork and data analysis, VCS concluded that chloride contamination of the concrete was the primary cause of deterioration for most concrete elements. Chloride contamination and observed steel section loss indicated an advanced stage of corrosion. Freeze-thaw damage also contributed to the deterioration of the FDR Drive concrete elements exposed to chlorides that likely accelerated chloride ingress to the depth of reinforcement. For the outrigger beams not exposed to chlorides, freeze-thaw was determined to be the primary deterioration mechanism.

VCS recommended several rehabilitation options, including electrochemical chloride extraction (ECE), installation of galvanic anodes, surface-applied galvanic protection, and impressed current cathodic protection. VCS has been working with H&H to develop cost estimates and service life projections for each potential rehabilitation option so that NYCDOT can decide which rehabilitation is right for them.