Lake Hume Dam

Services Applied by VCS Engineering

Project Description

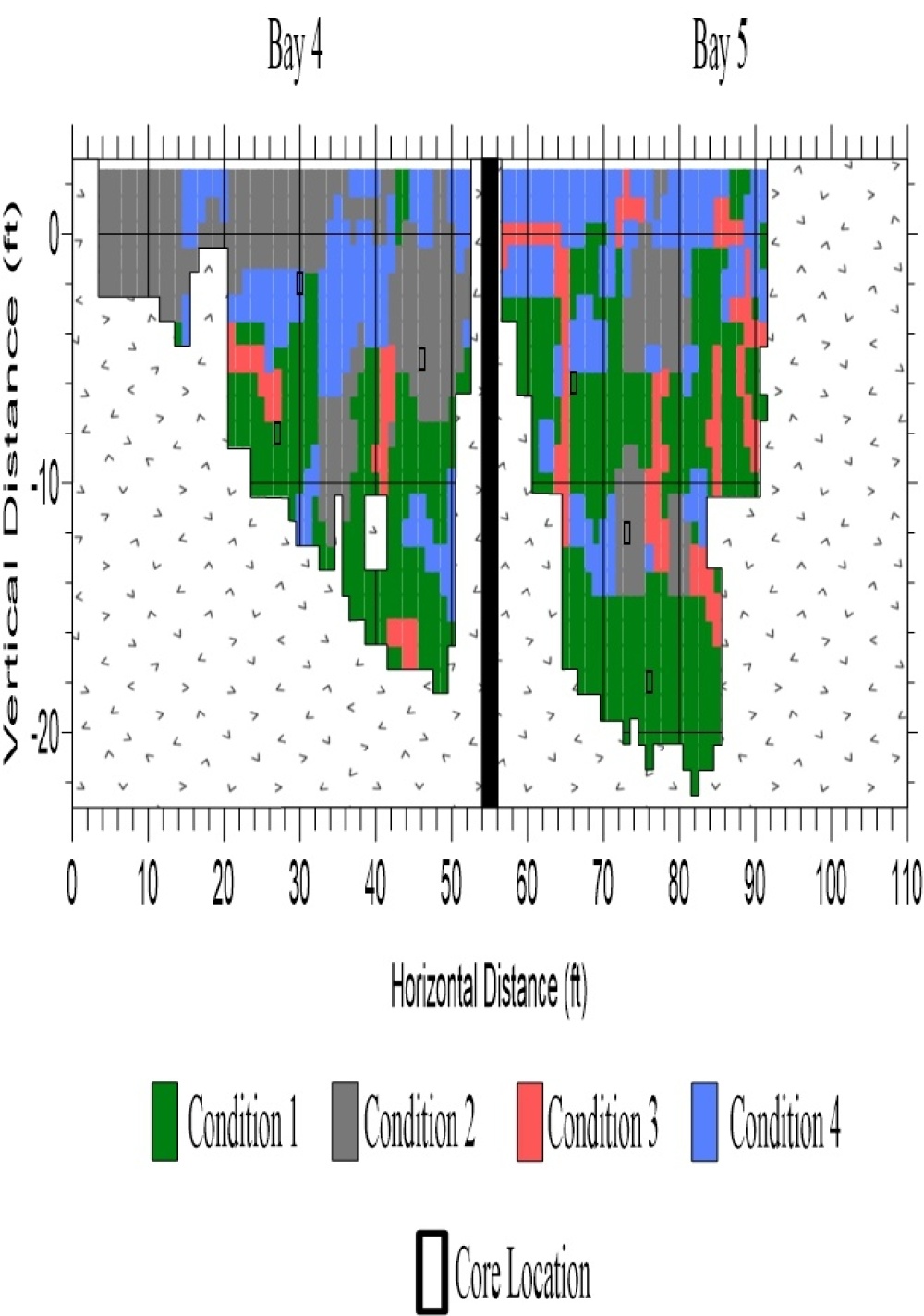

The Hume Lake Dam in Sequoia National Forest was designed by John S. Eastwood and constructed in 1908. It is the world’s first reinforced concrete multiple arch dam, comprised of 12 arches. The dam was undergoing a major restoration that included grout injection into the supporting bedrock and epoxy/urea silicate injection to fill voids in the dam wall. After the voids were filled, a PVC liner was installed on the upstream face of the dam. All these repairs were meant to stop the seepage that was observed on the downstream face of the dam. Vector Corrosion Services (VCS) was contracted by the United States Forest Services to perform testing on Bays 4 and 5 of the dam to evaluate the amount, distribution, and significance of voids and delaminations in the dam’s wall. Bays 4 and 5 are some of the larger more central bays on the dam and have been observed to have the most significant seepage issues.

Project Scope

To evaluate Bays 4 and 5 VCS conducted impact echo (IE) and pulse velocity (PV) of the haunch area. VCS also conducted infrared thermography (IR) testing on all 12 bays of the tank. IR allowed for the quick evaluation of the whole dam surface while IE/PV testing was focused in the worst two bays, 4 and 5. Verification cores were collected from the dam wall based on the IE/PV testing to help correlate the data with observed conditions. VCS was also asked to evaluate the remaining steel thickness of a steel outlet pipe that allows the release of water from behind the dam in Bay 6. This cross-section evaluation was conducted using an ultrasonic thickness device (UT).

Project Solution

VCS identified that there are large areas in the upper reaches of the dam haunch that have concrete deterioration in the form of delaminations and shotcrete failure. A map of these areas was provided to the Forest Services to aid them in the repairs. Additionally, the verification cores identified that original concrete of the dam implemented locally sourced granite for aggregate and that the particle sizes were quite large. As a result, significant consolidation voids were identified in the original concrete.

The UT identified that the steel intake pipe averaged about 26% section loss due to uniform corrosion activity. Additionally, pitting corrosion was observed on the tank and there were locations in which the cross-section had been reduced by approximately 50%.

The results of the testing was provided to the Forest Service to assist them in making rehabilitation decisions regarding the Lake Hume Dam.