Edmonton LRT Platform

Services Applied by VCS Engineering

Project Description

At several LRT platforms throughout Edmonton, Alberta, a restoration was being conducted to repair the reinforced concrete the platforms are constructed of. Corrosion had initiated in the steel reinforcement due to exposure of the platforms to de-icing chemicals. During the winter months, significant de-icing chemicals are placed on the platforms for passenger safety. These chemicals diffuse into the concrete and reach the steel reinforcement. Once sufficient quantity has reached the steel reinforcement, corrosion of the steel occurs. Corrosion will cause cracking, delamination, and spalling of the concrete. As part of the restoration work to these platforms to repair and stop this corrosion, corrosion potential measurements were conducted to locate the areas of active corrosion. During the initial corrosion potential surveys, the technicians performing the survey noticed strange readings. As a result, they consulted VCS, and VCS determined that stray currents were traveling through the platforms, causing the strange readings. VCS was hired to perform the rest of the corrosion potential surveys of each LRT platform and assess the presence of stray currents.

Scope

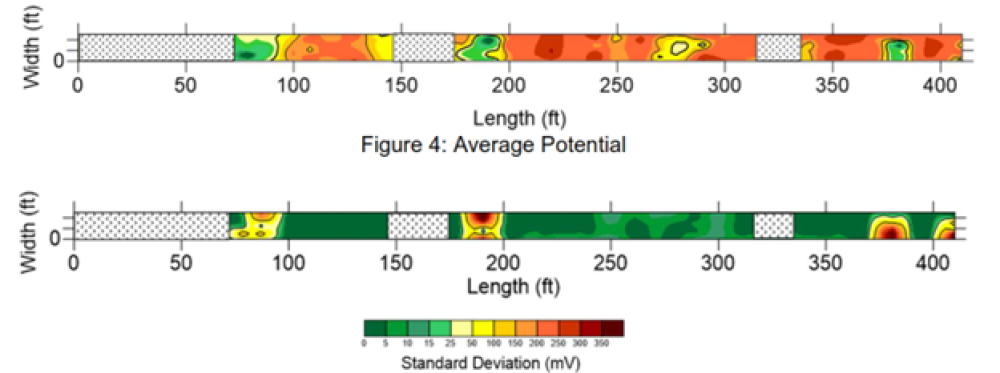

VCS perform corrosion potential measurements on four LRT platforms and also set up a data logger to monitor the potential of the reinforcement for stray-current. A data logger is required as stray-currents will have a different frequency and can occur temporarily, for example only as a train passes the station. Therefore, a datalogger capturing the potential measurement at a high frequency is required to determine if stray-currents are present. VCS set up various reference electrodes on a datalogger and monitored the potential of the steel.

Project Solution

VCS was able to locate the areas of corrosion and detect the presence of stray-current. As a result of these findings, VCS was hired to design a cathodic protection system for the platforms to mitigate the de-icing-induced concrete. The cathodic protection system was a fusion system that included an impressed current and galvanic phase for improved performance. For the stray-current issue, VCS designed zinc anodes installed at either end of the platform to allow the stray-current picked up by the platform to be discharged back to the ground without harming the platform.